From time to time, you may find that your cured resined piece has changed unexpectedly in appearance from clear to yellow. Why can cured epoxy resin turn yellow? More importantly, what can be done to help prevent yellowing? There are several different reasons why epoxy resin can appear discolored:

- Exposure to UV light

- Exposure to high temperatures

- Over torching

- Using a sealant that yellows

- Not allowing paint adequate time to dry

- Using titanium white paint

- Layering resin coats (which causes a bulking effect)

The most important step in preventing a resined piece from yellowing is to understand why it can happen. Let's take a closer look at the most common conditions that cause cured epoxy resin to appear yellow.

Why Did My Epoxy Turn Yellow?

1. Exposure To UV Light

UV light exposure is the most common cause of yellowing, with sunlight being the biggest culprit. UV light is powerful and when it hits resin, can break down the polymers causing gloss loss, delamination, cracking, surface chalking and yellowing. The more UV light the cured epoxy resin is exposed to, the worse the damage will be.

ArtResin is chemically engineered with 2 light stabilizers to protect against UV light's damaging effects: a UV Light Stabilizer and an advanced additive called HALS (or Hindered Amine Light Stabilizer.) The UV Stabilizer delays the effects from UV light, while the Hindered Amine Light Stabilizer discourages discoloration by interrupting the degradation process at the onset. Together, the UV Stabilizer and HALS in ArtResin are a powerful force to help mitigate the effects of UV exposure.

Best practice is to avoid exposing artwork to direct sunlight altogether. After all, putting your artwork in an environment that may cause damage doesn't make sense and makes the job much more difficult for ArtResin's UV stabilizers.

2. Exposure To High Temperatures

Continuous exposure to high temperatures or placing artwork too close to a heat source can cause discoloration in epoxy resin. Some examples of this include:

- Storing your artwork in a space that isn't climate controlled, such as outdoors or in an attic

- Hanging your piece above a heat vent

- Hanging your piece in a warm spot such as a conservatory or in a sunny window

- Hanging your piece under a light source that generates heat, such as gallery lights. The heat generated by the bulbs can eventually cause the resin to discolor in the spots where the light hits the resin.

Best practice is to keep cured resin art away from sources of heat for extended periods of time.

3. Over Torching

Over torching happens when a flame torch or heat gun is held too closely to a freshly resined surface. Over torching can cause resin to cure with a rippled effect and, in time, can lead to yellowing or discoloration. If your resined piece has only yellowed in certain spots and not throughout, those areas may have been over torched.

Best practice is to hold the torch a few inches away from the surface so that the flame is just kissing the resin. The bubbles should disappear right away - if they don't, move in a bit closer. Keep the torch moving in a back and forth fashion across the entire surface, as if you're ironing clothes. Remember, when it comes to torching, less is more!

4. Using A Sealant That Yellows

Sometimes it's not the resin that has yellowed but the sealant, resulting in a discolored appearance overall. In most cases, you don't need to use a sealant before applying ArtResin, however it's a good idea over paper that may absorb resin, over loose materials, and over natural objects (such as wood) that may release trapped air and cause bubbles. We recommend doing a test on a scrap piece before resining to determine whether you need to seal first.

Best practice when it comes to sealing includes:

- Choosing a sealant that dries clear

- Using a spray sealant on fragile artwork that could be damaged by brushing on sealant

- Choosing a sealant that's appropriate for your artwork - a sealant designed for an acrylic painting might not be suitable for a photograph.

-

Using a sealant that specifies "non-yellowing" on the label. We've had good results from the following non-yellowing sealants: Krylon Crystal Clear spray, Krylon Matte spray and Krylon UV Resistant spray.

5. Not Letting Paint Adequately Dry

Discoloration can occur if resin is applied to paint that isn't completely dry. Even if paint seems dry to the touch, this could simply be the initial skin that has formed over the surface. The paint in the center may still be evaporating and if it comes into contact with resin before it is sufficiently dried, the result could be a cloudy cure or eventual discoloration/yellowing.

Best practice is to allow the paint to completely dry before resining. If the paint gives under pressure, feels tacky, soft, or cool to the touch, this can be an indication that the paint has not dried all the way through. Dry time can be longer than one might think: depending on the temperature, humidity, and how thick the paint has been applied, it can take weeks (and even years in the case of oil paint) to completely dry.

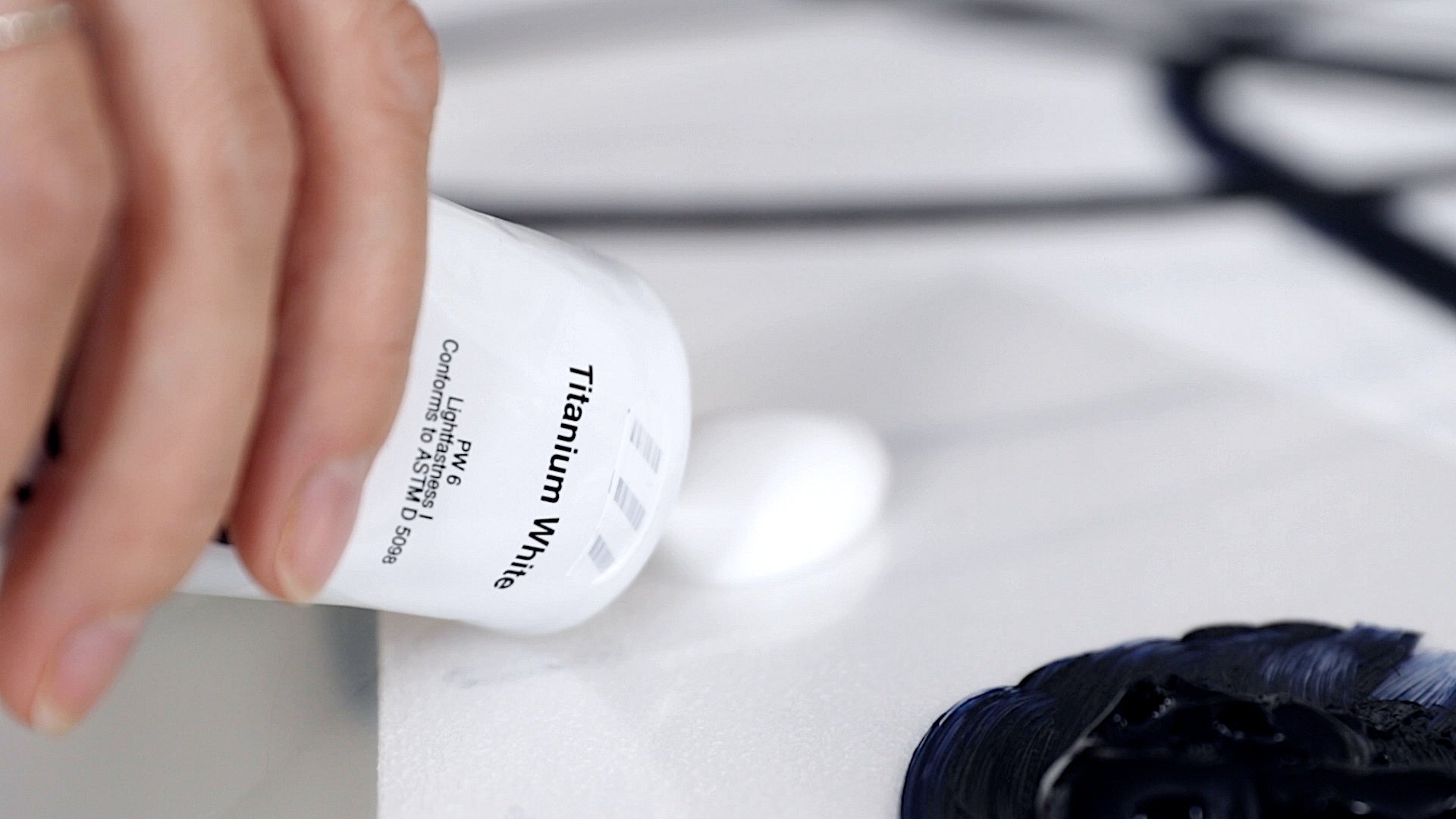

6. Using Titanium White

Yellowing can occur as a result of an interaction between Titanium Dioxide, found in titanium white paint, and ANY brand of epoxy resin. Ti02 acts as a catalyst in most situations and can accelerate natural degradation when in direct contact with the resin.

Best practice when using titanium white paint under resin is to apply an appropriate sealant to act as a barrier between the Ti02 and the resin.

7. Bulking in Layered Resin

Although ArtResin was designed as a surface coating and meant to be poured in thin applications, many artists like to get a thicker coat by pouring multiple layers. Be aware, however, that if resin starts to discolor, a thick layer can amplify even a gentle yellowing. Just as the ocean looks blue but a cup of water looks clear, the yellowing you see in a thick layer of resin can look worse than it is because you're seeing it in bulk.

Your Resin Has Yellowed ... Can You Fix It?

Unfortunately, once resin has yellowed, there isn't much that can be done to reverse it. You can try sanding out the yellowed resin (being careful not to damage your artwork) and applying a fresh coat: you may not be able to salvage a piece with badly yellowed areas, but you might be able to lessen the discoloration. Your best bet, however, is to limit UV light and heat exposure in order to slow down further yellowing.

Since most things on earth change in appearance as they age, no manufacturer of epoxy resin can guarantee that their product will never yellow. Our goal for ArtResin has always been to offer the best protection on the market against yellowing. We are confident in our product's performance because of the high quality ingredients and the chemistry behind our formula. Still, taking a few precautions will avoid compromising the yellowing protection inherent in ArtResin, and will help prolong the clarity of your work for the longterm.

Do you want to learn more about epoxy resin and yellowing? Read our guides below:

- What Is HALS & UV Stabilization?

- What Can You Do With Yellowed Hardener & Resin?

- Why Do Some Brands Of Epoxy Resin Turn Yellow?

- Anti-Yellowing Epoxy Resin

ArtResin: The Original Epoxy For Resin Art.