Why Do Resin Brands Yellow Over Time?

Click here to view third party yellowing test data featuring various popular epoxy resin brands.

Chances are if you've landed on this page, you've had a beautiful piece of art turn yellow after using a resin product that's not specifically formulated for use over creative projects. Total bummer....

see more

Which Epoxy Resin is Best for Artwork?

When choosing an epoxy resin to cover your painting, photo, wood project, print, or other kind of craft, you may be tempted to go with whatever is cheapest. But be warned—what may at first seem relatively inexpensive could wind up costing you a ton over the long run in damaged artwork!

How Resins...

see more

Top 4 ArtResin Ideas! No. 3 - Coating a Mounted Photo

Here's how to mount and resin a photo! Video tutorial included!

First, you need a wooden panel (as opposed to a canvas). Clamp your print down on one side and lift up the other side so you can use spray adhesive on the panel. Use PLENTY of spray adhesive! Then let go of the print, letting ...

see more

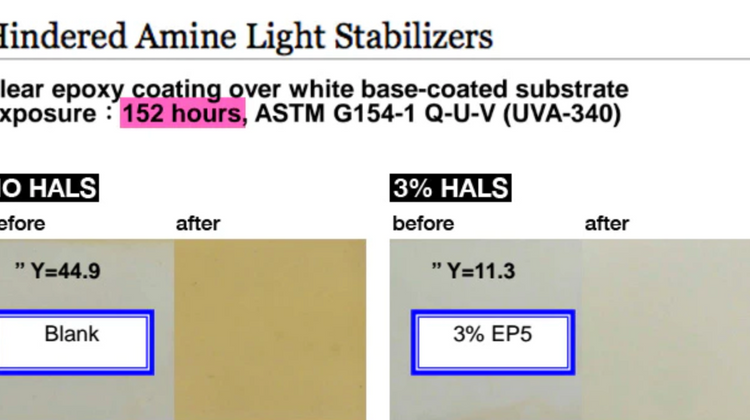

Create Stunning Art with ArtResin's Advanced Ant-Yellowing Technology

We're making a big deal out of our new ArtResin formula because, unlike every other resin on the market, ours is chemically engineered to offer advanced protection against yellowing! This product has the right mix of ingredients to keep your work significantly clearer. Let me explain how it works.....

see more

How is our new ArtResin formula better in terms of yellowing?

March 2015

It's been a week since our new epoxy resin formula launched, and we've been asked the same question A LOT (and rightly so): How is this new formula better in terms of yellowing, specifically? Glad you asked. We have a video in production explaining all of this, but I thought it would be h...

see more