Knowing which type of resin to use for your project can be challenging, especially for resin art beginners. There are a wide variety of epoxy resins available, so the wrong choice could cost you valuable money and time, and may even ruin your creative work.

Our casting resin vs. epoxy resin guide will help you understand the difference between casting resin and epoxy resin. Both products are popular among resin artists and DIY resin enthusiasts. They are, however, formulated for different uses, with distinct qualities, pouring methods, and curing times.

Once you're aware of the differences, you’ll know exactly which resin to use for making a variety of resin projects!

Are Epoxy And Resin The Same Thing?

Epoxy resin is one of several types of resin available on the market, each designed for different purposes ranging from artistic to industrial.

However, when most people refer to "resin", they are usually referring to epoxy resin. Epoxy resin is widely used by artists, crafters, woodworkers, and hobbyists and has become very popular in recent years.

💡 TIP: Other types of resin available include UV Resin, Polyester Resin, and Polyurethane Resin. To learn more about these resins and their applications, please see our blog Types Of Resin And Their Uses.

Are Epoxy Resin And Casting Resin The Same Thing?

Casting resin is a type of epoxy resin. Just as there are different types of resin, there are also different types of epoxy resin, each formulated for a specific purpose.

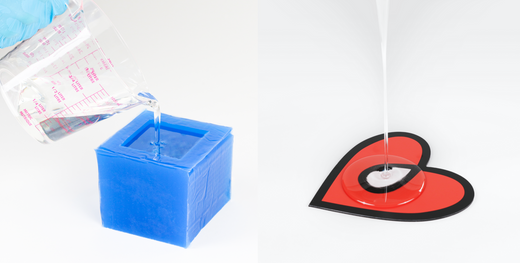

Casting resin has a very low viscosity like water, making it ideal for projects that require a thick pour, such as pouring into a deep mold or encapsulating an object in resin. Its thin consistency takes longer to cure but makes it easy for bubbles to escape to the surface and pop, resulting in a crystal-clear cast.

Coating resin (sometimes called laminating resin) is also type of epoxy resin. It is a strong, durable medium-viscosity resin meant to withstand wear and tear and is best suited for surfaces that see regular use. It is often used for industrial purposes, such as sealing concrete floors, but there are non-toxic, food-safe coating resins available for use on countertops, table tops, and bar tops.

Art resin is another type of epoxy resin. It's a high quality coating resin designed specifically for artists and crafters. Resin for art has a honey like consistency, making it easy to control the flow. The best quality art resins are intended for use at home and are non-toxic, low odor and contain no solvents. High quality art resins also have light stabilizers added to help prevent resined artwork from yellowing due to UV light exposure.

Top Differences Between Epoxy Coating Resin And Casting Resin

Apart from the intended use, there are some other key differences between coating resin and casting resin that all DIY epoxy enthusiasts should know.

| Feature | Casting Resin | Epoxy Coating / Art Resin |

|---|---|---|

| Viscosity | Low viscosity (water-thin), ideal for deep pours and encapsulations | Medium to high viscosity, ideal for coating surfaces without running over edges |

| Mixing Ratio | Usually 2:1 or 3:1 resin to hardener | Typically 1:1 (equal parts), some coating resins may be 2:1 |

| Cure Time | Slow cure (up to 7 days depending on depth and temperature) | Faster cure: dry to touch in 24 hours, full cure in 72 hours |

| Working Time | Longer working time due to slow cure; varies by brand and environment | Shorter working time; may decrease in warm environments |

| Max Pour Depth | Thick pours (1–4 inches per layer or more) | Thin pours only (⅛" to ¼" per layer) |

| Hardness | Varies by formula; can be hard or slightly flexible depending on use | Hard and scratch-resistant for coating; art resin is more flexible |

| Air Bubbles | Low viscosity allows bubbles to rise and pop easily during curing | Thicker viscosity may trap bubbles if poured too thick; use a torch for surface bubbles |

| UV Resistance | Depends on brand; yellowing is more visible on thick clear castings | High-quality art resins contain UV stabilizers to prevent yellowing |

| Heat Resistance | Varies by formulation; check tech sheet before using on hot surfaces | Higher heat resistance; some coating resins are made for countertop use |

| Best Used For | Deep molds, embedding, figurines, river tables, encapsulations | Tabletops, bar tops, artwork, trays, coasters, wall art |

Viscosity: How Thick Are Coating, Casting and Art Resins?

Viscosity refers to the thickness (or flow resistance) of epoxy resin. Some resins have a low (thin) viscosity and some have a high (thick) viscosity.

Casting resin has a thin viscosity and is meant for deep pours. The benefit is twofold: its water thin consistency allows bubbles to escape to the surface and also prevents the resin from overheating as it starts to cure. However, its fluidity also means that casting resin can run off the edges of a project: an efficient solution to this problem is to pour it into a mold or build a frame in order to hold the resin in place.

Coating and art resin typically have a medium-high viscosity and are meant to be poured in thin layers over a surface. Its slightly thicker consistency allows for more control when spreading this type of epoxy, preventing it from running over the edges. When working with tinted resin, such as in ocean art, the thicker viscosity also prevents the colors from blending and becoming muddy.

💡TIP: It's important to avoid pouring thick layers of either coating or art resin: not only are you likely to experience trapped bubbles, but the resin might overheat to the point that it could cure immediately, become yellow, and possibly even crack.

Mixing Ratio

Epoxy resin comes in two parts: the resin and the hardener, sometimes referred to as the base and catalyst or Parts A and B. Mixing the two components prompts a chemical reaction that takes the mixture from a liquid to a solid. The mixing ratio refers to the amount of each part required for this process to take place.

Most art resins on the market have a simple-to-follow 1:1 mixing ratio, meaning you need equal amounts of resin and hardener. Coating resins can have a 2:1 mixing ratio, calling for 2 parts resin to 1 part hardener. Most casting resins have a 2:1 or 3:1 mixture. Read the manufacturer’s instructions to ensure the resin is accurately measured and thoroughly mixed. If not, the resin won’t cure correctly.

Curing Time

Cure time refers to the amount of time that it takes for the resin to dry and become fully hardened all the way through. Cure time is affected by both pour thickness and temperature.

Coating and art resins are typically dry to the touch within 24 hours and fully cured at 72 hours. Casting resin has a much slower curing rate: it is typically dry to the touch within 72 hours, but can take up to a week to cure completely.

💡TIP: Please note that resins designated safe for food contact are not considered food safe until the product has fully cured. Consult the manufacturer’s instructions for cure times specific to each brand.

Working Time

Working time refers to the time after mixing the resin before it sets and becomes too thick to work with: once the resin sets, it will be too thick to pour or spread, and you will no longer be able to remove bubbles from the mixture.

Temperature and mass can affect working time: for example, warming the resin in a water bath or working on a hot day can reduce the working time of the epoxy resin. Leaving the mixed resin to stand in the mixing container for a long time will prompt the curing process and may even cause it to overheat and cure immediately in the cup. To avoid this, pour the mixed resin into several smaller containers to reduce the volume. It’s also wise to have your workspace and project ready to go, with all tools on hand, so that you can pour as soon as you’ve finished mixing the resin.

Whether it’s casting, coating, or art resin, each brand is formulated differently, and has a specific working time. See the instructions before you measure and mix to know exactly how much working time to expect.

Maximum Pouring Depth

The pouring depth is the maximum recommended amount of resin that you can pour in a single layer.

Often referred to as “deep pour resin”, casting resin allows for thick pours of several inches for each application. Casting resin is a good option for projects that require a clear, deep pour, such as casting molds and figurines or for embedding applications.

In contrast, epoxy coating or art resin typically has a maximum pouring depth of ⅛ to ¼” per application. To achieve a thick layer with art or coating resin, you will need to pour in layers until you reach the thickness you desire. However, be aware that you may see lines in between the layers. For more information, please see our blog 3 Ways To Get A Thick Layer Of Resin

💡TIP: It’s important to follow the manufacturer’s instructions and not pour coating or art resin thicker than the recommended amounts. If the resin poured too thick, you may end up with trapped bubbles, and the resin may overheat, turn yellow or even crack.

Hardness

One the main qualities common to almost all resins is, once cured, it is strong and durable, but depending on its intended use, some resins may cure harder and more indent resistant than others.

Coating resins are generally formulated to be hard and scratch-resistant, offering long-lasting protection and performance for high traffic surfaces such as floors and countertops.

On the other hand, art resins are formulated to be a little more flexible: it's meant to coat artwork that will be hung on the wall or on display and will not experience much handling.

Casting resins can vary in their overall hardness, depending on their formula. The mixing ratios (we previously mentioned 2:1 and 3:1 as the most common ratios) that can affect how hard they get.

💡TIP: To determine a resin’s hardness, look for its Shore Rating. To learn more about Shore Ratings, read the blog Hard, Durable, Solid, Strong, Epoxy Resin.

Air Bubbles In The Resin

All resins are susceptible to bubbles if label instructions and best practices are not followed.

When it comes to art and coating resin, follow the manufacturer’s instructions for pouring recommendations: these are typically 1/8" to 1/4". If the layers are thicker than this, it’s difficult for bubbles to make their way to the surface, and you may end up with trapped bubbles in the cured resin.

Casting resin is formulated for thick pours, with a thin consistency so that bubbles can float to the surface and pop. Just as coating and art resin have a recommended pour thickness, so does casting resin. It typically ranges from 1-4” and can be even higher in deep pour casting resins. Follow the recommended pour thickness for best results and to avoid unwanted bubbles.

💡TIP: You can reduce the number of bubbles by slowly mixing your resin. When working with art or coating resins, Use a flame torch to pop surface bubbles.

💡TIP: Resin loves warm temperatures. Cold resin is full of deep microbubbles that will not release or get torched out. Ensure the resin and the room you’re working in are at room temperature or slightly above, and maintain this temperature for the first 24 hours.

💡TIP: Cover porous materials, like wood, with a sealant before you apply resin: this will create a barrier in all the cavities, gaps, and porous areas and prevent trapped air from releasing in the form of bubbles.

💡TIP: Apply a thin sealing coat to items you intend to encapsulate before pouring casting resin over them, especially if these items have areas where air can become trapped.

UV Resistance

Resins vary in terms of their UV resistance and protection against yellowing. ArtResin, for example, is well-known for offering superior protection against the effects of UV light.

Whether you’re working with coating resin, art resin, or casting resin, choose a resin that contains UV light stabilizers. This is especially important for casting resin as yellowing from UV light exposure is more evident on clear, thick castings that do not contain pigment or tint.

💡TIP: To help maintain long-term clarity, avoid exposing cured resin projects to direct sunlight.

Heat Resistance

Heat resistance refers to the maximum recommended temperature that resin can be exposed to. Resins are all formulated with a different heat tolerance depending on their intended purpose.

ArtResin, for example, is intended for use on artwork and can tolerate a maximum temperature of 120°F or 50°C once cured. Temperatures higher than this may cause pieces to become a little flexible, but they will harden up again once they return to room temperature.

On the other hand, coating resin - intended for countertops, bar tops, tables, and other surfaces - is formulated to withstand high heat. Please read High Heat Resistant Clear Epoxy Resin to learn more about heat-resistant epoxy resin.

💡TIP: Since many resins will start becoming soft at about 110-150°F (or around 50°C), always check the manufacturer’s technical data sheet, particularly if you intend to use them on surfaces that may come in contact with hot objects.

The Bottom Line

Now that you know the main differences between casting, coating, and art resin, we hope it’s easier to make the right choice for your next resin project.

A few points to remember

1. Resins are all formulated differently for different purposes and will exhibit specific characteristics depending on their desired performance. For best results, choose a resin that meets the project requirements for which you intend to use it.

2. Read the manufacturer’s instructions and follow them accurately for the best results.

3. Wear the appropriate personal protective equipment, as outlined on the product’s label. Wear a respirator if you’re working in an area with poor ventilation. 4) The more high-quality the resin you use, the better and long-lasting your artwork will be in the end: pick your ArtResin products today and start creating art with confidence!

Are you new in resin art? Read our guides below to help you get started:

- Resin Art Beginners's Guide

- Butane vs Propane Torch

- Top Resin Mistakes Made By Beginners

- What Is The Best Resin For Beginners

- Top 10 Easy Resin Projects For Beginners

- How to Resin On Canvas For Beginners

- Resin Materials For Beginners

- What Resin Art Sells The Best?

- Resin Art VS Acrylic Pour

- How To Make Money As An Artist

ArtResin: The Original Epoxy For Resin Art.